巴基斯坦宣布新禁令,重大政策转变的背后与动因分析

文章目录

宣布新禁令的深度解析

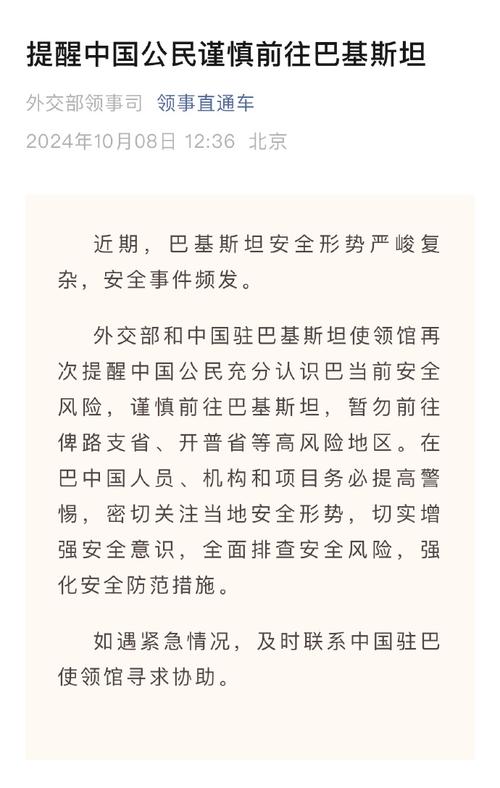

近年来,巴基斯坦面临着诸多内外部挑战,包括经济压力、政治动荡以及安全局势的不确定性,在这样的背景下,政府宣布了一项重大政策转变——新禁令的出台,引起了国内外的广泛关注,本文将对该政策进行深入解析,探讨其背后的动因、可能带来的影响以及面临的挑战。

巴基斯坦政府近期宣布的新禁令涉及多个领域,在经济领域,为了应对国内严重的经济困境,政府不得不采取措施限制某些行业的外资流入,以减少外汇压力,在政治领域,新禁令可能是为了加强政府对某些敏感领域的控制,以维护政治稳定,安全局势的恶化也是促使政府作出这一决策的重要因素之一。

经济压力下的必然选择

巴基斯坦经济近年来面临诸多挑战,包括外汇储备不足、通胀压力上升以及经济增长放缓等,在这种情况下,政府采取新禁令是为了保护国内产业免受外部冲击,同时减少外汇支出,这一决策虽然短期内可能会带来一些负面影响,但从长远来看,对于促进国内经济发展具有重要意义。

政治稳定的需要

巴基斯坦政治局势一直较为动荡,各种政治势力之间的争斗不断,新禁令的出台可能是政府为了加强控制某些敏感领域,以减少政治不稳定性对国家的冲击,通过加强对这些领域的监管和控制,政府可以确保政治稳定,为国家的长远发展奠定基础。

安全局势恶化的影响

巴基斯坦的安全局势一直备受关注,近年来,恐怖袭击和武装冲突不断发生,给国家带来了巨大压力,新禁令的出台可能是政府在安全局势恶化背景下的应急措施,以维护国家的安全和稳定。

二、新禁令的影响与面临的挑战

新禁令的出台对巴基斯坦内外都将产生一定影响,对于国内而言,新禁令可能会促进国内产业的发展,减少外部冲击对国内经济的负面影响,但同时,这也可能导致某些行业受到冲击,需要政府采取有效的措施进行平衡和协调。

国内产业的新机遇与挑战

新禁令为国内产业提供了新的发展机遇,政府可以通过加强对某些行业的监管和控制,为国内企业创造更加公平的市场环境,这也要求国内企业提高自身竞争力,适应新的市场环境,新禁令也可能导致某些行业受到冲击,需要政府采取措施进行扶持和援助。

国际社会的反应与压力

新禁令的出台也将引起国际社会的关注,虽然巴基斯坦的经济和政治稳定对于国际社会而言具有重要意义,但新禁令可能会引发一些国家的担忧和批评,巴基斯坦需要与国际社会进行充分沟通和协调,以缓解外部压力,同时寻求国际支持和合作。

三、深度分析与批判性思考

新禁令的出台反映了巴基斯坦政府在应对内外部挑战时的决策和选择,这一政策也面临着诸多挑战和争议,新禁令可能会限制外资的流入和技术创新的发展,对巴基斯坦的长期经济发展产生负面影响,政府需要加强监管和控制某些领域的同时,也需要保障公民的权利和自由不受侵犯,新禁令的实施需要政府加强执行力度和透明度,以确保政策的公正和有效。

巴基斯坦新禁令的出台是政府在应对内外部挑战时的必然选择,这一政策也面临着诸多挑战和争议,我们需要对政策进行深入分析和批判性思考,以促进政府的决策更加科学和合理,巴基斯坦也需要与国际社会进行充分沟通和协调,以缓解外部压力并寻求国际支持和合作。