Guest cleo

Model: 2002 Toyota Corolla

Recent work done: 2 weeks ago serpentine belt was replaced (Note, there were no problems with it or engine, the belt was just worn and needed replacing. This was done by an auto shop mechanic, not the car owner. Also note that the mechanic apparently had a difficult time tightening the belt).

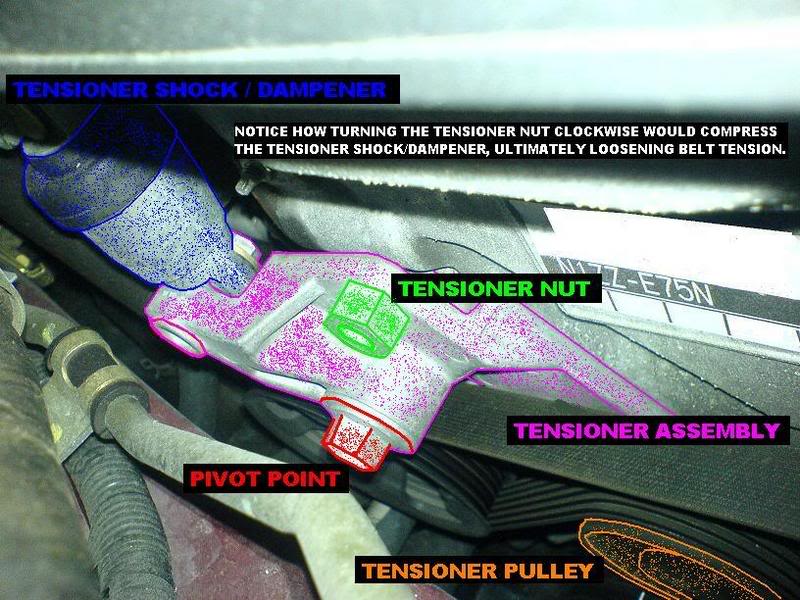

Problem now (2 weeks later): Noticed the pivot bolt (holding the bracket on the serpentine belt tensioner) sheared off/broke off inside the engine block. (Note, we were just taking a look under the hood, out of curiosity, and were looking over the serpentine belt when we noticed the broken bolt.)

Questions:

1. What could have caused the pivot bolt that holds the bracket on the serpentine belt tensioner to shear off/break off inside the engine block?

2. How often do these steel pivot bolts in this location, fail on their own?

3. What is the likelihood, that this bolt failure was caused by an action that the mechanic who replaced the serpentine belt 2 weeks ago did (ie tightened the bolt too much, sheared it, etc)?

4. How would one repair this? I assume the engine needs to be pulled and the bolt will need to be drilled/tapped out? How difficult is this? What are the chances that the engine block could be damaged by attempting this?

5. Approximately how much would be reasonable for this repair to cost?

How often does a machine/auto shop mechanic typically deal with this problem? (ie is this a common problem for them to deal with?)

6. NOTE: The original mechanic, who replaced the serpentine belt 2 weeks ago, is denying that it was his fault in any way (Note: We've been using this mechanic for about 8 years and have trusted him and his work)?

Based on the timing of this bolt breaking -- it only seems logical that the TIMING of the replacement of the serpentine belt and the ACTIONS of the mechanic in doing this, are in some way, responsible for this bolt's breaking? The bolt was not broken at the time that they replaced the belt. Otherwise they would have noticed it in some way, correct?

(The only thing the mechanic said/suggested (since he wouldn't admit any fault or possible fault) was that we should look online to see if Toyota recalled pivot bolts on 2002 Corollas. He seems to think the steel bolt failed naturally. He didn't refer us to another shop that could give us a deal on removing the bolt, since they don't have the machinery/drills necessary.)

7. Any advice would be greatly appreciated. THANKS!