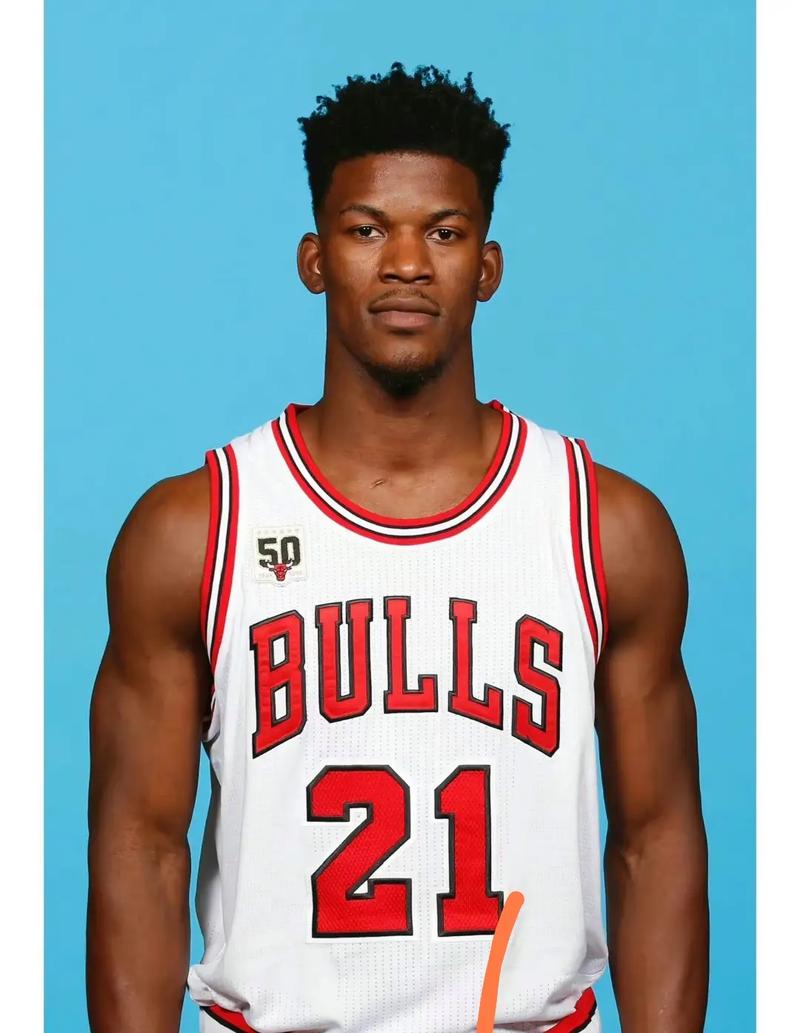

吉米·巴特勒,这位NBA的传奇人物,以其不屈不挠的精神和出色的篮球技艺,赢得了无数球迷的喜爱和尊重,他的职业生涯充满了挑战和成功,让我们一起来深入探讨一下这位篮球巨星的关键词和他的故事。

关键词:坚韧不屈

巴特勒是一位典型的篮球巨星,他的坚韧不屈精神是他成功的关键,无论是在篮球场上还是在生活中,他总是保持着积极的态度和坚定的决心,面对困难和挫折,他从不放弃,而是选择勇敢地面对,不断地挑战自我,超越自我,这种坚韧不屈的精神,使他能够在激烈的篮球比赛中始终保持高昂的斗志,为球队赢得胜利。

批判性分析

从批判性的角度来看,巴特勒的成功并非偶然,他的成功并非仅仅依赖于天赋和运气,更多的是他坚韧不屈的精神和不懈的努力,在篮球场上,他总是能够保持专注和专注力,不断地追求进步和提高,他善于观察和学习,不断地提高自己的篮球技艺和战术水平,他也非常注重团队合作和沟通,与队友们一起努力,共同为球队的目标而奋斗。

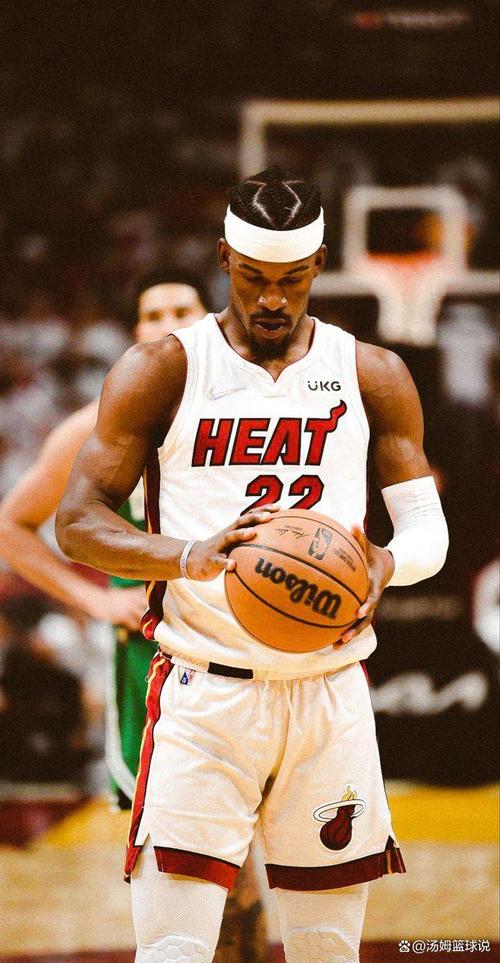

深度分析

除了坚韧不屈的精神外,巴特勒还展现出了出色的领导能力和人格魅力,他总是能够带领球队走向胜利,为球队带来胜利和荣誉,他的领导能力不仅仅体现在战术层面上,更体现在他的个人魅力和人格魅力上,他总是能够鼓舞人心,激发队友们的斗志和潜力,他也非常注重个人形象和品德修养,始终保持着一颗谦逊、正直、善良的心。

个人情感与个性化表达

在深入了解巴特勒的过程中,我们不难发现他的人格魅力和精神品质深深地打动着我们,他的故事让我们看到了坚韧不屈、勇敢拼搏、积极向上的精神面貌,他的成功并非偶然,而是他坚持不懈的努力和不断追求进步的结果,他也展现出了出色的领导能力和人格魅力,成为了一位备受尊敬和爱戴的篮球巨星。

吉米·巴特勒是一位非常出色的篮球巨星,他的故事让我们看到了坚韧不屈、勇敢拼搏、积极向上的精神面貌,他的成功并非偶然,而是他坚持不懈的努力和不断追求进步的结果,他也展现出了出色的领导能力和人格魅力,成为了一位备受尊敬和爱戴的球员,我们应该向他学习这种坚韧不屈的精神和积极向上的态度,为我们的生活和事业带来更多的动力和信心。