在动荡的金融市场中,准确预测黄金和白银的价格走势至关重要。这两种贵金属的价格波动受到多种因素的复杂影响,包括市场供求关系、全球经济形势、地缘政治事件以及货币政策等。

对于投资者而言,掌握黄金白银价格趋势有助于制定有效的投资策略。通过技术分析和基本面分析相结合的方法,投资者可以识别市场趋势,判断是买入、卖出还是持观望态度。例如,在经济衰退时期,黄金通常被视为避险资产,价格可能上涨;而白银则更多地受到工业需求的影响。

企业,特别是那些从事黄金白银开采、加工或贸易的企业,也需要密切关注价格波动。准确的价格预测可以帮助企业优化生产计划、管理库存以及制定定价策略,从而降低因价格波动带来的风险。合理的风险管理策略对于企业的长期稳定发展至关重要。

从宏观经济的角度来看,黄金白银价格可以作为重要的经济指标。价格的变动可以反映通货膨胀预期、货币政策变化以及市场信心等因素。例如,持续的通货膨胀通常会推高黄金价格,因为黄金被视为对抗通货膨胀的有效工具。

然而,预测黄金白银价格并非易事,市场充满了不确定性。

地缘政治风险:国际冲突、贸易战等地缘政治事件可能引发市场恐慌,导致黄金白银价格剧烈波动。投资者需要密切关注全球政治局势,并根据形势调整投资策略。

宏观经济数据:关键经济指标,例如GDP增长率、非农就业数据以及通货膨胀率,都会影响黄金白银的价格。意外的经济数据公布可能导致市场预期发生变化,从而引发价格波动。

货币政策:央行的货币政策,例如利率调整和量化宽松政策,会对黄金白银价格产生间接影响。宽松的货币政策通常会降低美元的价值,从而推高以美元计价的黄金和白银价格。

为了应对市场的不确定性,投资者和企业可以采取多种策略:

多元化投资:不要将所有资金都投资于黄金白银,而是将投资组合分散到其他资产类别,以降低风险。

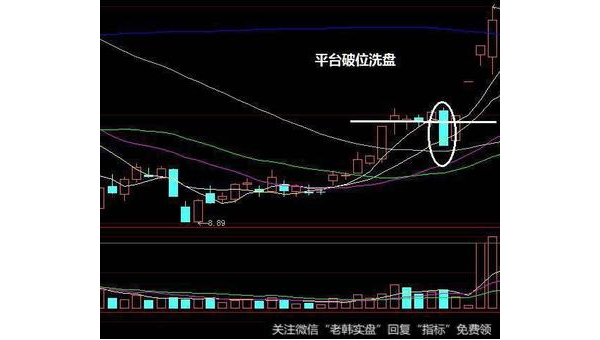

技术分析:利用图表分析、技术指标等工具来预测价格走势。

基本面分析:关注宏观经济数据、地缘政治事件以及货币政策等因素对价格的影响。

风险管理:制定合理的风险管理策略,例如设定止损点,以控制潜在的损失。

持续学习:不断学习和更新市场知识,以便更好地应对市场变化。

总之,黄金白银价格趋势的分析是一项复杂的任务,需要投资者和企业综合运用多种分析方法,并充分考虑市场的不确定性因素。只有这样,才能做出更明智的投资决策,并有效地管理风险。