黄金,作为一种重要的投资避险资产,其价格波动受多种因素交织影响,呈现出复杂的规律。要准确把握黄金价格的走势,投资者需要深入理解并综合分析这些因素。

一、宏观经济形势:经济周期与黄金价格的跷跷板

全球经济形势是影响黄金价格最主要的因素之一。在经济繁荣时期,投资者风险偏好较高,资金往往流向股票等高收益资产,黄金的避险功能相对减弱,价格可能下跌或维持平稳。然而,当经济衰退、通货膨胀压力加大或金融危机爆发时,黄金作为保值避险工具的价值凸显,投资者会大量涌入黄金市场,推高其价格。例如,2008年全球金融危机期间,黄金价格大幅上涨,正是由于投资者寻求避险资产的强烈需求所致。

二、货币政策:央行行动与黄金价格的互动

央行的货币政策对黄金价格的影响同样显著。宽松的货币政策,如降低利率、增加货币供应量,会导致货币贬值预期增强,从而刺激投资者购买黄金以保值增值,进而推高黄金价格。相反,紧缩的货币政策则会抑制黄金价格上涨,甚至可能导致其下跌。美联储的加息降息政策往往会对国际黄金市场产生重大影响,投资者需要密切关注。

三、地缘政治局势:国际冲突与黄金避险需求

地缘政治风险也是影响黄金价格的重要因素。国际冲突、地区战争、恐怖主义等事件都会引发市场恐慌情绪,增加投资者的避险需求,从而推高黄金价格。历史上,许多地缘政治事件都导致黄金价格出现短期或长期的波动,投资者需要关注国际局势的动向。

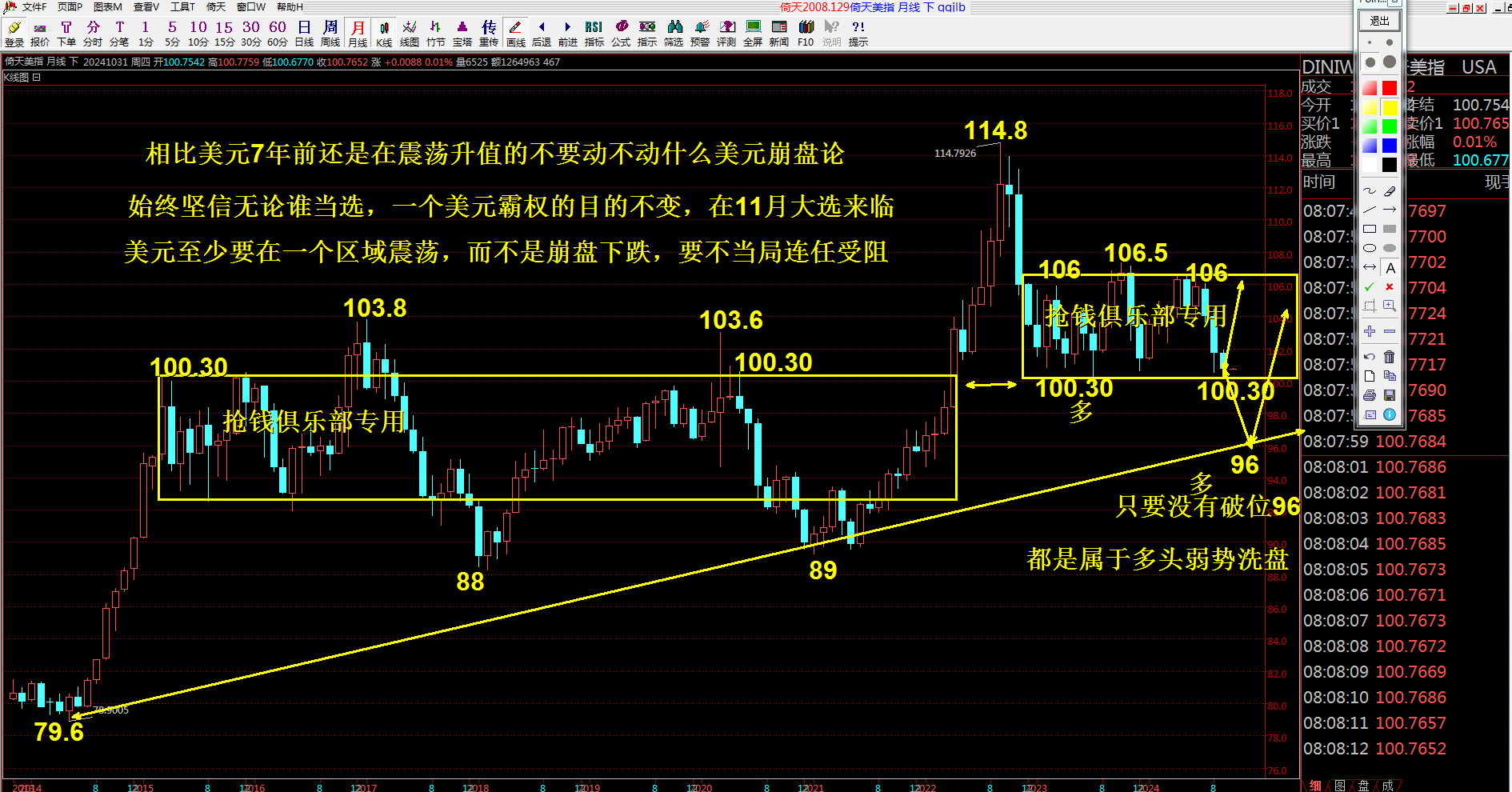

四、美元走势:美元与黄金的负相关关系

美元与黄金价格通常呈现负相关关系。美元走强时,黄金价格往往承压下跌,因为美元是国际储备货币,其升值会削弱黄金的相对价值。而美元走弱时,黄金价格则可能上涨,因为投资者会寻求替代的保值资产。

五、通货膨胀:购买力下降与黄金保值功能

通货膨胀是影响黄金价格的重要长期因素。当通货膨胀率上升时,货币购买力下降,黄金作为抗通胀资产的价值提升,价格通常会上涨。因此,通货膨胀预期也是影响黄金价格的重要因素。

六、供求关系:黄金产量与市场需求

黄金的供求关系同样会影响其价格。黄金产量下降或市场需求增加,都会导致黄金价格上涨;反之则可能导致价格下跌。矿业生产、回收利用以及珠宝首饰等行业的黄金需求都会影响市场供求。

七、技术分析:短期波动与交易策略

除了上述宏观因素,技术分析也对黄金价格的短期波动有指导意义。投资者可以通过观察黄金价格的移动平均线、K线图、相对强弱指标(RSI)、MACD等技术指标,来辅助判断市场的趋势和买卖时机。但是,技术分析并不能完全预测黄金价格的走势,需要结合基本面分析综合判断。

八、投资策略:综合分析与风险管理

投资黄金需要综合考虑上述各种因素,并结合自身风险承受能力制定合理的投资策略。切忌盲目跟风,要根据自身情况进行分散投资,并做好风险管理。

免责声明: 本文仅供参考,不构成任何投资建议。投资有风险,入市需谨慎。