Yeah, mixing a little Synchromesh is a trick to get the syncros to "mesh" faster. But that generally works better if the trans is grinding between gears.

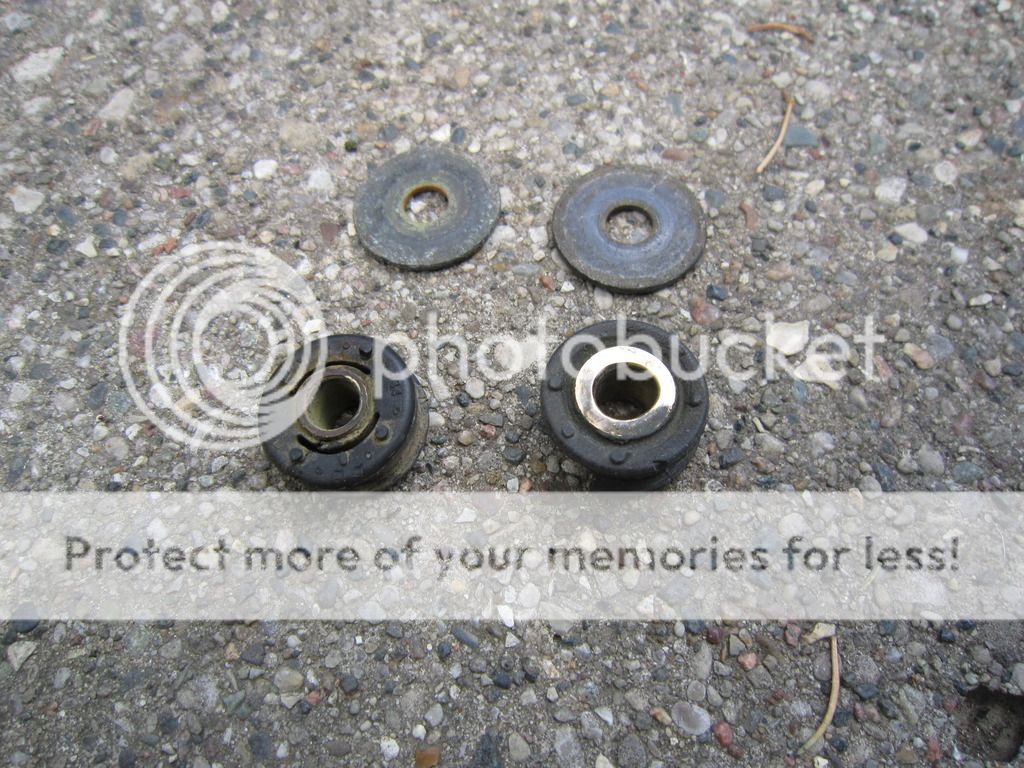

Possible it could be a bushing issue on the shift cables (both on the shifter plate and the transaxle). If the bushings are worn, it makes it act like the shifter is not fully following the gate, like pulling on the side of the shifter as you run through the gears. Could cause it to hang up, feel "sticky" or "notchy".

Also, could still be a worn syncro - not unheard of on this generation of Corolla. The gear oil you have in there - Redline MT-90 - is pretty much the best you could run, IMO. Same stuff that I'd run in my own manual gearboxes.

Could try running some of the gear oil you drained out through a coffee filter - see if you can see any brass materials being shaved off. That would definitely tell you the syncro is bad.

I'd check the shift bushing first - then go to being a back syncro. Nothing really to lube around there, other than the shift bushings - which tend to already be self-lubricating. If you notice that shifting is a little "off" in all the gears, then I'd really suspect the bushings. If only 3rd gear gives you problems - that leans more toward being a bad syncro - but I wouldn't rule out anything else.

The bushing replacement is the same for most Toyotas - there should be lots of videos and DIY guides floating around online.